Have burners also entered the 'smart era'?

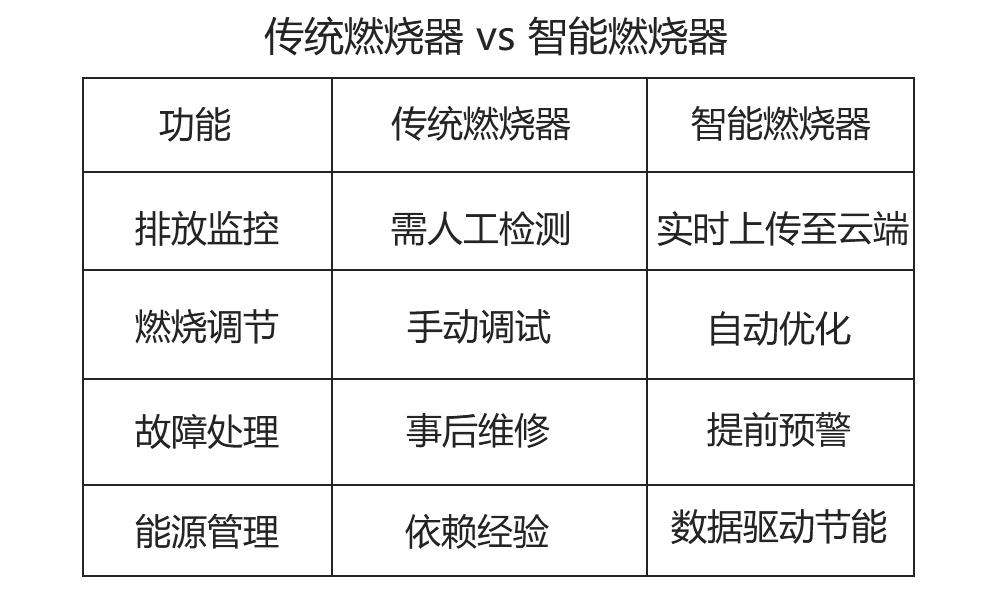

Driven by the 'dual carbon' goals and Industry 4.0, traditional low-nitrogen burners are ushering in an era of intelligent transformation. In the past, companies might have only focused on low nitrogen emissions and thermal efficiency of the burners, but now, intelligent features such as remote monitoring, automatic adjustment, and predictive maintenance are making burners more efficient and worry-free.

The burners of the future are not only environmentally friendly but can also 'optimize their own operation'! Today, let's talk about how smart burners combine low-nitrogen technology with the Internet of Things to bring new value to enterprises.

1. What is an intelligent burner?

Intelligent burner = Low-NOx combustion technology Internet of Things (IoT) Big data analytics

Core features include:

○Real-time monitoring: Data such as NOx emissions, combustion efficiency, and fuel consumption can be visualized in the cloud.。

○Automatic adjustment: Dynamically optimize the air-fuel ratio according to load changes to maintain efficient and low-NOx combustion.

○Remote control: Adjust parameters via mobile phone/computer without on-site operation.

○Fault warning: AI analyzes operational data to detect potential issues in advance.

2. The 4 Core Technologies of Intelligent Burners

1. Internet of Things (IoT) Remote Monitoring

Sensor network: Real-time collection of data such as temperature, pressure, NOx, CO, and O₂.

Cloud platform: data visualization, supports centralized management across multiple devices (such as monitoring all boilers in a corporate group).

Mobile alerts: Abnormal data is pushed to the phone to prevent unplanned downtime.

2. AI Algorithm Optimizes Combustion

Dynamic air-fuel ratio control: Automatically adjusts the ratio of fuel to air according to load changes, ensuring it always operates in a highly efficient and low-nitrogen state.

Adaptive learning: Training models with historical data to adapt to different fuel qualities (such as fluctuations in natural gas calorific value).

3. Predictive Maintenance

Vibration/Temperature Analysis: Monitor the status of key burner components and predict issues such as nozzle blockages and fan malfunctions.

Maintenance Reminder: The system automatically generates maintenance plans to reduce unexpected downtime losses.

Data comparison: Traditional maintenance methods require an average of 8 hours to repair faults, whereas the intelligent system can provide a 3-day advance warning, reducing the time to 1 hour.

4. Digital Twin

Virtual simulation: Simulate the combustion process in digital models to optimize design parameters.

Remote debugging: Engineers guide on-site operations through a virtual burner, reducing service costs.

3. What industry pain points can intelligent burners address?

1. Environmental compliance pressure

Pain point: Environmental protection departments require NOx data to be networked, and manual recording is prone to errors.

Intelligent solution: emission data is automatically uploaded to the regulatory platform, generating compliance reports.

2. Rising energy costs

Pain point: Fuel accounts for 30%-50% of production costs, and traditional burners are highly wasteful。

Smart Solution: AI optimization reduces gas consumption by 5%-15%, saving hundreds of thousands of yuan annually.

3. Insufficient operations and maintenance personnel

Pain point: It is difficult to hire professional boiler engineers, resulting in slow fault response.

Smart solution: Remote diagnostics and AR guidance allow ordinary employees to handle common issues.

4. Future Trends: Hydrogen Energy Adaptation and Carbon Neutrality

The next step for intelligent burners is to be compatible with green fuels.

Hydrogen combustion: solving the problems of fast hydrogen flame speed and high NOx formation through intelligent regulation.

Carbon Tracking: Combining blockchain technology to record carbon emission data and assist companies in achieving carbon neutrality.

5. How should companies plan the deployment of intelligent burners?

1. Assess requirements: Do the existing devices support intelligent upgrades?

2. Choose a plan:

- Lightweight: Add IoT modules (suitable for budget-constrained companies).

- Fully integrated: directly replace the intelligent burner (preferred option for new projects).

3. Focus on ROI: Calculate energy-saving benefits and renovation costs, with a typical payback period of 2-3 years.

Conclusion

Intelligent technology is an inevitable upgrade for low-nitrogen technology. Smart burners are not only a technological iteration but also an innovation in management models. They enable enterprises to shift from 'passive environmental protection' to 'proactive optimization,' reducing emissions while enhancing economic benefits.

近日,加科燃烧器圆满完成江苏君乐宝乳业有限公司2台低氮燃烧器项目的安装与调试工作,为乳业生产的高效、环保运行注入···

近日,加科燃烧器顺利完成对青海云天化国际化肥有限公司2台25吨低氮燃烧器的改造项目,标志着双方在环保与能源效率提升···