In recent years, with increasingly stringent environmental protection policies, the emission standards for equipment such as industrial boilers and kilns have been continuously raised, making low-nitrogen burners gradually an essential tool for enterprises to save energy and reduce emissions. However, many people may not be clear: how exactly do low-nitrogen burners reduce nitrogen oxide (NOx) emissions? What makes them superior to traditional burners?

Today, let's take an in-depth look at the core technology of low-nitrogen burners and see how it helps businesses meet environmental standards and even save on fuel costs!

1. Where do nitrogen oxides (NOx) come from? Why should they be controlled?

Before understanding low-nitrogen burners, we first need to understand: what are nitrogen oxides (NOx)? Why are they strictly regulated?

1. The main sources of NOx

NOx is mainly produced during high-temperature combustion processes, especially in equipment such as industrial boilers, gas turbines, and kilns. When nitrogen (N₂) and oxygen (O₂) in the air react at high temperatures, NOx is generated, which mainly includes:

Thermal NOx (reaction of N₂ and O₂ at high temperatures)

Fuel NOx (produced from the combustion of nitrogen-containing compounds in the fuel)

Prompt NOx (briefly formed during the combustion of hydrocarbon fuels)

Among them, thermal NOx is the main source, and its formation is closely related to the combustion temperature—the higher the temperature, the greater the amount of NOx formed.

2. The Dangers of NOx

1. Environmental pollution: NOx is an important precursor of smog (PM2.5) and ozone (O₃).

2. Health hazards: Can cause respiratory diseases and even cancer.

3 Acid rain: NOx dissolves in water to form nitric acid, leading to soil and water acidification.

Therefore, countries have successively introduced strict standards, such as:

China: Key area industrial boiler NOx emission limit ≤ 50mg/m³** (GB 13271-2014)

EU: Latest BAT (Best Available Techniques) requires NOx ≤ 30 mg/m³

Traditional burner NOx emissions are usually between 150-300 mg/m³, which obviously cannot meet the requirements. As a result, low-NOx combustion

technology has emerged!

2. Core technology of low-NOx burners: How to reduce NOx?

The core objective of low-nitrogen burners is to reduce combustion temperature and suppress NOx formation, mainly using the following technologies:

1. Staged Combustion

Principle: Divide the combustion process into a fuel-rich zone (reduction zone) and an oxygen-rich zone (combustion zone) to avoid high temperature concentration.

Stage one: Fuel burns under oxygen-deficient conditions, producing CO and H₂, at a relatively low temperature, reducing NOx formation.

Level 2: Introduce the remaining air to ensure complete fuel combustion.

Effect: NOx can be reduced by 30%-50%.

2. Flue Gas Recirculation (FGR)

Principle: Part of the low-temperature flue gas (mainly composed of CO₂ and N₂) is reintroduced into the combustion zone to reduce oxygen concentration and combustion temperature.

Internal circulation: The burner is designed with an internal recirculation structure.

External circulation: the flue gas is returned to the combustion zone through a fan.

Effect: NOx can be reduced by 40%-60%, especially suitable for gas boilers.

3. Premixed Combustion

Principle: The fuel and air are fully premixed before entering the combustion zone, ensuring more uniform combustion and avoiding localized high temperatures.

Traditional burner: diffusion combustion, high flame temperature, high NOx.

Premixed burner: uniform flame temperature, significant reduction in NOx.

Effect: NOx can be controlled below 30 mg/m³, but the air-fuel ratio needs to be precisely controlled.

4. Low-Nitrogen Combustion Head Design

Through specially designed combustion heads (such as porous nozzles and swirl flame-stabilizing structures), the flame becomes more dispersed, reducing the peak temperature.。

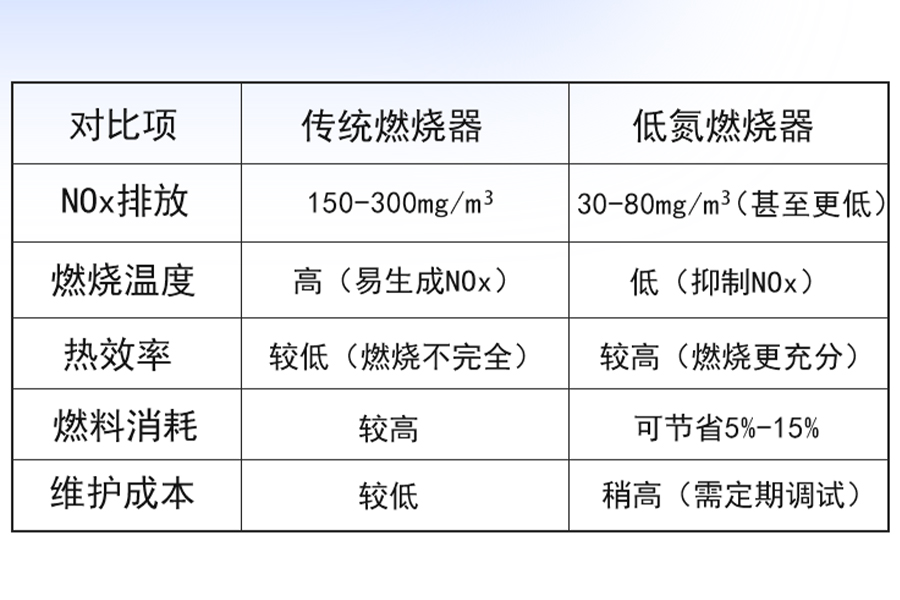

3. Low-Nitrogen vs. Traditional Burners: Comparison of Environmental Protection and Economic Efficiency

Conclusion:

Environmental advantages: NOx emissions reduced by more than 50%, easily meeting national standards.

Economic advantage: In the long term, fuel savings can offset the cost of modifications.

4. Which industries are suitable for low-nitrogen burners?

Industrial boilers (chemical, textile, food processing)

Heating boilers (hotels, hospitals, schools)

Kiln (ceramics, glass, metallurgy)

Power Plant (Gas Turbine Low-NOx Retrofit)

5. How should companies choose the appropriate low-nitrogen burner?

1. Check emission standards: Choose according to local environmental protection requirements (e.g., ≤50mg/m³ or ≤30mg/m³).

2. Check the fuel type: natural gas, diesel, biomass, etc., are compatible with different technologies.

3. Check the heat load: match the actual demand of the boiler or furnace.

4. Consider the brand and service: Choose suppliers with established cases to ensure after-sales support.

Conclusion

Low nitrogen burners are not only an environmental necessity but also a powerful tool for enterprises to reduce costs and increase efficiency. With continuous technological upgrades (such as hydrogen combustion and intelligent control), low nitrogen burners will play an even more important role in the process of achieving carbon neutrality in the future!

近日,加科燃烧器圆满完成江苏君乐宝乳业有限公司2台低氮燃烧器项目的安装与调试工作,为乳业生产的高效、环保运行注入···

近日,加科燃烧器顺利完成对青海云天化国际化肥有限公司2台25吨低氮燃烧器的改造项目,标志着双方在环保与能源效率提升···