Burners are important devices used in conjunction with heat equipment such as industrial oil-fired boilers, gas-fired boilers, and asphalt mixing plants. Burners ensure the stable ignition and complete combustion of fuel. Therefore, to suppress the generation of NOx, attention must be paid to the type of burner. Over the years, Jaco burners have been developed with continuously improving low-nitrogen technology. Currently, Jaco low-nitrogen burners are divided into the following types:

Jaco Self-Recirculating Burner

There are two types of GAKO self-recirculating burners: one uses the pressure of the combustion-supporting air to draw part of the combustion flue gas back into the burner, where it mixes with air for combustion. Because of the flue gas recirculation, the heat capacity of the combustion flue gas is high, the combustion temperature decreases, and NOx is reduced; the other type allows part of the flue gas to directly enter recirculation within the burner and be incorporated into the combustion process. This type of burner can both suppress nitrogen oxides and save energy.

Jakko stage burner

The staged combustion burner is designed based on the principle of staged combustion, which involves mixing fuel and air in segments for combustion. The combustion deviates from the stoichiometric ratio in order to reduce the formation of NOx.

Jacobs staged flame burner

The principle of the Jaco segmented flame burner is to divide the flame into several smaller flames. Relying on the characteristic of small flames having a large heat dissipation area and lower flame temperature, it helps reduce 'thermal NO formation.' At the same time, the smaller flames shorten the residence time of gases such as oxygen and nitrogen within the flame, significantly inhibiting both 'thermal NO' and 'fuel NO' formation.

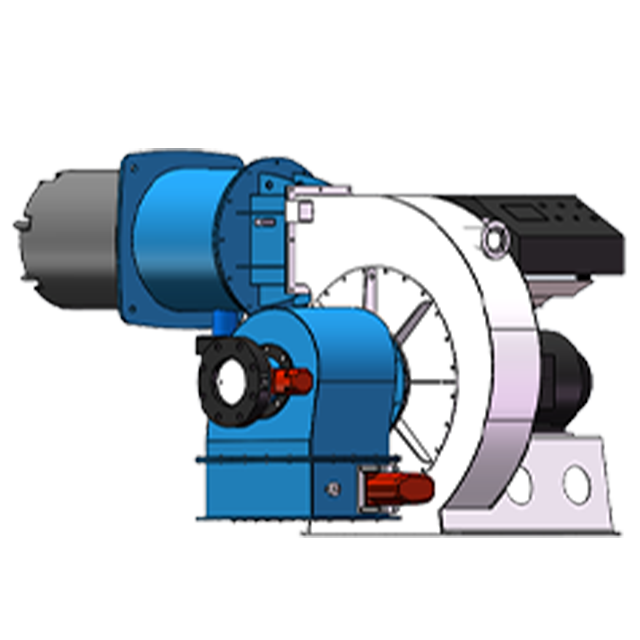

Jakco low-nitrogen burners are divided into: HS/HS(W) ultra-low nitrogen burners, HS light oil/gas ultra-low nitrogen burners, and HS heavy oil/gas ultra-low nitrogen burners.

The ultra-low nitrogen burner adopts a world-leading vacuum pump principle to recirculate the flue gas after combustion for secondary combustion. It increases the internal flue gas recirculation from the previous 15% to 30%, eliminating the need for external FGR pipes, and uniformly controls the furnace temperature at an appropriate level, thereby achieving low-nitrogen combustion. This solves issues such as condensation corrosion and combustion safety associated with FGR, representing a revolutionary innovation in combustion technology.

Scope of application: three-pass boilers, center-reburning boilers, cast iron modular boilers, vacuum hot water boilers, indirect hot boilers, and hot air furnaces.

Jiake actively carries out environmental technology research and development for low-nitrogen burners and has formed a low-nitrogen burner product system covering multiple industries. For more professional knowledge about boiler burners, you are welcome to visit.燃烧器厂家-低氮燃烧器-锅炉燃烧器-非标燃烧器-加科首页 (gacoch.com)

State Power Investment Group Co., Ltd. (referred to as "State Power Investment") is a super large st···

The coal chemical industry has a wide variety of products, a large economic output, and a wide coverage area, ···

24 hours dedicated to serving you

15563365608(wechat)

Address:No. 9 Ningshi Road, Zhangqiu District, Jinan City, Shandong Province

Email:admin@gacoch.com